The European Union’s In Vitro Diagnostic Regulation (IVDR) 2017/746), which replaces the current In Vitro Diagnostic Directive (IVDD 98/79/EC), introduces risk–based classification for IVD devices, in addition to new and required Technical Documentation.

Specifically, the seven (7) classification rules under the IVDR have resulted in four (4) new risk groups for IVD products, which determine a device’s conformity assessment route and product-specific technical specification requirements. While classification is typically the primary concern for IVD Sponsors, when a device falls within Classes B, C or D, it has important implications for the Notified Body and manufacturer that must be considered.

Section 1: Device Classification—Shaping the Technical Documentation

IVDR Classes A, B, C and D take into account the intended purpose of a device and their inherent risks, which are based on risk level:

- Low-risk (Classes A and B), including self-tests

- Moderate-risk (Class C)

- High-risk (Class D)

Manufacturers must classify their devices in accordance with Annex VIII (1.1) implementing rules. These rules state that “classification is governed by the intended purpose of a device, where devices used in combination or accessory with a device are to be classified separately; Calibrators and Controls used with a device are the same class as the device of intended use, and devices with multiple intended purposes with multiple classes, the higher class will be used.’

It is noted that the manufacturer is responsible for classifying a device (Annex VIII 1.7); NOT the Notified Body or Competent Authority. Interestingly, Article 47 confirms that if a manufacturer and Notified Body cannot agree on the classification, the Competent Authority will make the final determination.

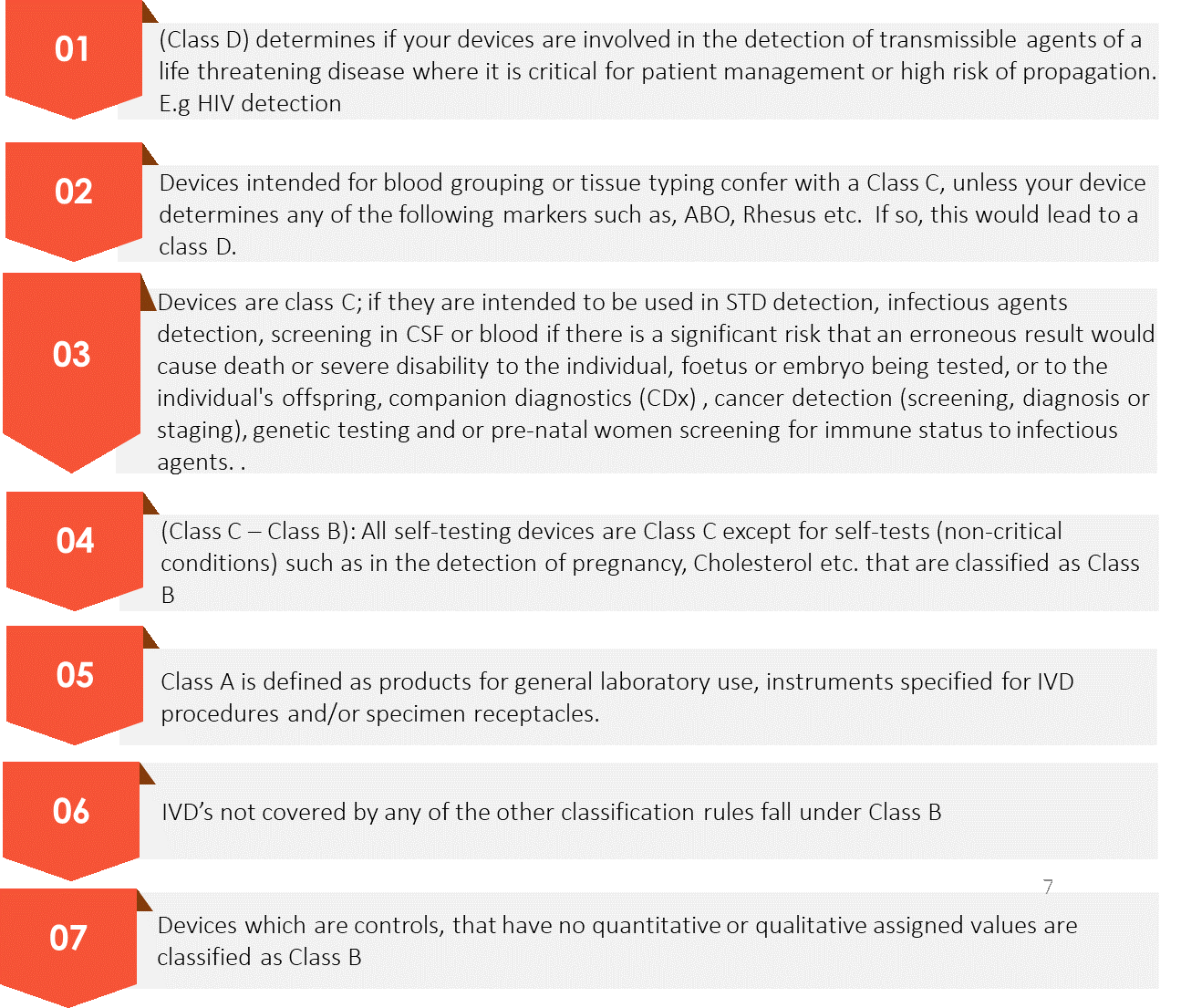

Classification Rules: Annex VIII 2.0

Classification Rules (Annex VIII 2.0)

Devices that are Class C or D have a more regular Surveillance Assessment on top of the technical requirement, which include:

- Performance Evaluation Report (PER), referred to in Article 56

- Periodic Safety Update Report (PSUR), referred in Article 81

- Summary of Safety and Performance, referred on Article 29(1)

These documents are expected to be updated at least annually, and updates are to be gathered using the Post-Market Surveillance (PMS) plan, referred in Article 79.

Section 2: Technical Documentation—Obligations within the IVDR

Article 10 of the IVDR provides clarification on specific Technical Documentation obligations: “Manufacturers shall draw up and keep up to date the Technical Documentation for these devices. The Technical Documentation shall be such as to allow the conformity of the device with the requirements of this Regulation to be assessed.”

a) Importance of Technical Documentation and the Conformity Route

The IVDR expects Technical Documentation to play quite a significant role in the conformity route for manufacturers. Furthermore, the EU Declaration of Conformity in the Technical Documentation should be available for Competent Authorities to review prior to placement on the market.

“Manufacturers shall keep the Technical Documentation, the EU Declaration of Conformity and, if applicable, a copy of the relevant certificate, including any amendments and supplements, issued in accordance with Article 51, available for the Competent Authorities for a period of at least 10 years after the last device covered by the EU Declaration of Conformity has been placed on the market.”

b) Full Disclosure on Design, Production and Quality Testing

Annex II identifies Technical Documentation requirements for manufacturers, which can be found in the following sections:

- Device Description and Specification

- Information Design and Manufacturing

- General safety and Performance Requirements (GSPR)

- Benefit-Risk Analysis and Risk Management

- Product Verification and Validation

This information can range from the very basic—such as what the device is—to more complex information such as variety and design and manufacturing details. For the latter, design information must allow design stages applied to the device to be understood by the reader, as well as information on the manufacturing process (production, assembly, final product testing and packaging of the final product). Note: If manufacturers utilize a sub-contractor for production, this information must be represented in all documents, including the QMS status.

c) Higher Emphasis on Risk Management Strategy

The Benefit-Risk Analysis, as part of Risk Management, introduces a higher level of risk requirement for manufactures, with reference to Section 3 of Annex I. Quite similar to ISO 14971:2012, with regards to expectations, it includes identification of risks such as foreseeable misuse, mitigation of risks—with preference for design reduction to eliminate the risk as far as possible (Design control)—and communication of any residual risks to the user (such as IFU).

It also describes the benefit/risk ratio, meaning that the risk should be controlled to have benefits that outweigh any remaining risk. The IVDR does make note that Risk Management should align with the Performance Evaluation, as specified in the preamble (32).

d) Maintaining Continuity on Performance Evaluation Reports

Product verification and validation are at the core of conformity for any IVD device, and the IVDR does not play this any differently. IVDR obligations for manufacturers are to demonstrate the following in the device documentation:

- Analytical performance

- Clinical performance

- Scientific Validity

- Stability

Additionally, clinical evidence is based on data surrounding Scientific Validity, Analytical Performance and Clinical Performance of the device. It should also be noted that Performance Evaluation is continuous throughout the lifecycle as updates occur from scientific or medical practice; reassessments should occur as well. This information is incorporated into the PMS documentation, another piece of documentation required in a device’s technical file.

e) Need for a Strong Post-Market Performance Follow-up (PMPF) Plan

Article 56 and Annex XIII describe the new Post-Market Performance Follow-Up (PMPF) plan requirements, including how they should be defined within a Quality Management System (QMS). The PMPF can vary at a high degree within the QMS due to the type of device and the classification of the device being reviewed. For example, plans can stand alone or, if a manufacturer has a family of products that are similar, a standardised plan could be appropriate.

Article 79 and Annex III address what is to be included in the PMS plan and its links in other aspects of the regulation such:

- Risk Management

- Scientific Validity

- Clinical Performance

- Analytical Performance (Performance Evaluation)

- Corrective and Preventive Actions (CAPA)

- Safety Monitoring

(These should all be linked through the PMS plan with the PER, as discussed earlier.)

Conclusion

IVDR technical requirements are significantly shifting the IVD industry, and these changes require a more thorough approach to IVD development that ensures that claims are accurate and devices are safe.

Demonstrating device performance through Technical Documentation must be satisfied, with Clinical Performance, Scientific Validity and Analytical performance playing key roles. It should also be noted that Technical Documentation does not end with a Sponsor’s submission, but should constantly be updated as it evolves throughout the device lifecycle. Finally, classification of a device can influence the documentation required, and manufacturers should be very aware of the classification rules to classify products accurately and efficiently.

How Can NAMSA Help?

NAMSA is the industry leader in driving successful regulatory outcomes through effective interactions with the EU Commission and Notified Bodies. Our internal teams of medical device development and IVD experts communicate with EU entities nearly every day and are the most experienced in industry at accelerating regulatory submissions and approvals for IVD manufacturers.

Additionally, NAMSA provides support to market authorization holders, including implementation of IVDR requirements, IVDR conformity strategies and compilation of appropriate Technical Documentation for submission to Notified Bodies. NAMSA’s team of medical writers and regulatory specialists can provide full support to assist with all vital IVDR activities and processes.

Learn more about NAMSA’s IVDR resources here.

Warren R. Jameson, PhD

Over 15 years experience in IVD research, development, manufacturing, regulatory affairs and quality management. Served in Research and Development as well as Quality and Regulations Manager ensuring compliance with legislation, managing quality documentation, risk assessment, risk management and audits. Expert in reviewing technical files and guiding IVD sponsors for IVDR compliance. Creating technical documentation such as Performance Evaluation Plans (PEP) and Reports (PER) for IVD devices to be used as part of technical file submissions for IVDR compliance and to carry out performance evaluation. Significant experience in gap analysis reviews of analytical performance and clinical performance data and determination of the data is to the latest guidelines for performance, acceptable to IVDR standards and advise on solutions. Clinical performance creation including review of clinical performance protocol, studies and literature to determine the needs of devices and any gaps for IVDR compliance or US submissions. Scientific Validity report creation with search and review of scientific literature for analyte link to pathological or physiological conditions as stated in the IVDR for legacy and novel devices.